Mochini o Ikemetseng oa Tlhahiso ea Pizza

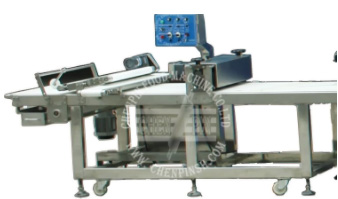

1. Hlama Conveyor Conveyor

■ Ka mor'a ho kopanya hlama ke phomolo bakeng sa 20-30 min.'Me ka mor'a ho belisoa e behoa holim'a Hlama e fetisang Sesebelisoa.Ho tloha sesebelisoa sena e ntan'o fetisetsoa ho li-roller tsa hlama.

■ Ho ikamahanya ka tsela e iketsang pele ho fetisetsoa ho leqephe ka leng.

2. Pre Sheeter & Continuous sheeting rollers

■ Leqephe le se le sebetsa ka har'a lirolara tsena tsa maqephe.Li-roller tsena li eketsa hlama ea gluten e hasana le ho kopanya.

■ Theknoloji ea Sheeting e ratoa ho feta mokhoa oa setso hobane sheeting e fana ka melemo ea bohlokoa.Sheeting e etsa hore ho khonehe ho sebetsana le mefuta e mengata ea hlama, ho tloha ho 'mala o motala' ho ea ho hlama e lomositsoeng pele, tsohle li le boemong bo phahameng.

■ Ka ho sebelisa li-sheeders tse se nang khatello ea kelello le theknoloji ea laminating, u ka finyella ha e le hantle hlama leha e le efe le sebopeho sa bohobe se lakatsehang.

■ Letlapa le tsoelang pele: phokotso ea pele ea botenya ba letlapa la hlama e etsoa ke sheeter e tsoelang pele.Ka lebaka la lirolara tsa rona tse sa tsitsang, re khona ho sebetsana le mefuta ea hlama ka liperesente tse ngata tsa metsi.

3. Pizza Cutting le Docking Disc Thepa

■ Cross roller: ho lefella phokotso ea lehlakore le le leng la liteishene tsa ho fokotsa le ho lokisa letlapa la hlama ka botenya.Letlapa la hlama le tla fokotseha ka botenya le ho eketseha ka bophara.

■ Seteishene sa ho fokotsa: botenya ba letlapa la hlama bo fokotsehile ha bo feta ka li-rollers.

■ Sehlahisoa se sehang le ho emisa (ho etsa li-disc): lihlahisoa li khaoloa ka letlapeng la hlama.Docking e etsa bonnete ba hore lihlahisoa li hlahisa bokaholimo ba tsona bo tloaelehileng 'me li etsa bonnete ba hore ha ho bubble holim'a sehlahisoa nakong ea ho baka.Litšila li khutlisetsoa ka conveyor ho ea bokellang.

■ Ka mor'a ho seha le ho emisa, e ntan'o fetisetsoa mochineng oa ho hlophisa terei e ikemetseng.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)