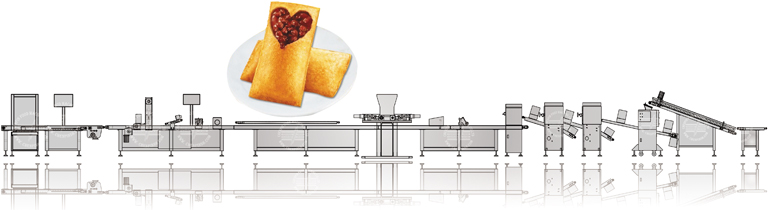

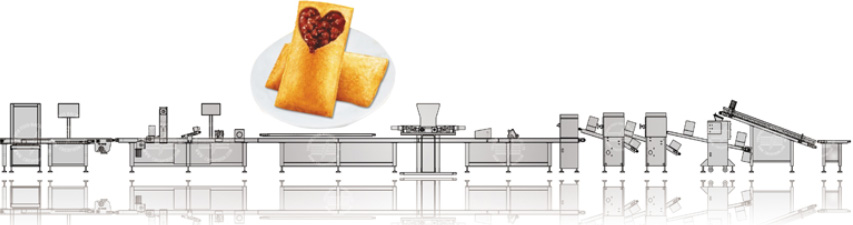

Pie & Quiche Production Line Machine

CPE-3100 Automatic Bean Pie Production Line

|

Size |

I (L)18,588mm * (W)3,145mm * (H)1,590mm II (L)8,720mm * (W)1,450mm * (H)1,560mm |

|

Electricity |

3 Phase,380V,50Hz,12kW |

|

Application |

Read Bean Pie, Apple Pie, Taro Pie |

|

Capacity |

14,000(pcs/hr) |

|

Pie weight |

50(g/pcs) |

|

Model No. |

CPE-3100 |

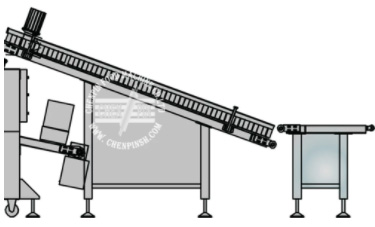

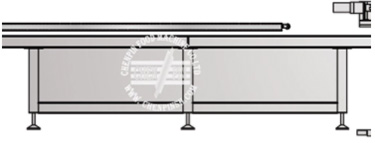

1. Dough Trans Conveyor

After Mixing of dough it is then place here on the conveyor belt and transfer to the next part of the line i.,e continuous sheet rollers

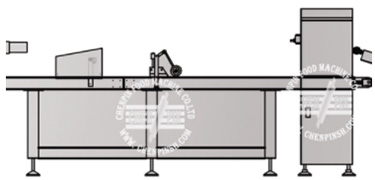

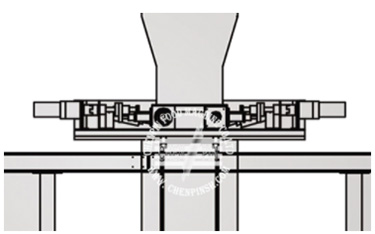

2. Continuous sheeting rollers

Sheet is now process in these sheet rollers. These roller enhances dough gluten extensively spread and mix.

3. Dough sheet Extending conveyor

Here Dough is extensively extend into thin sheet. And is then transfer into the next production unit of production line.

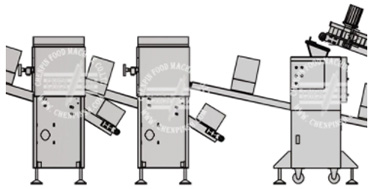

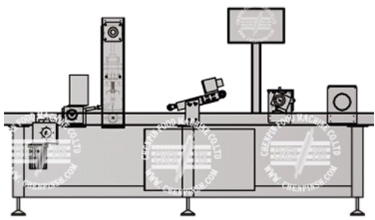

4. Stuffing machine

■ Pie stuffing is dropped on the lower dough skin of pie.

■ Continuously, discontinuously or in spots – fillings ranging from soft and creamy to solid are placed on the dough sheet in one to six rows. Even difficult filings such as meat and vegetables can be processed gently without crushing. It is quick and easy to clean.

5. Dough stacking

■ After mixer is dropped on the lower skin it is then start covering(stacking) layer on the mixer and lower skin.

■ You cut the dough sheet lengthways in a number of strips. The filling is placed on every second strip. Don’t need of any toboggan to place one strip on top of the other. Second strip to sandwich pie is automatically made by the same production line. The strips are then cross cut or stamped into shapes.

6. Molding and vertical cutter

Pie shaping/molding and cutting is done in this unit.

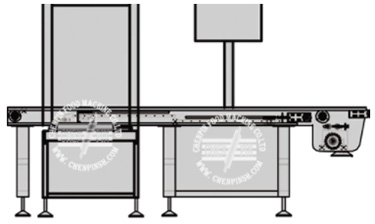

7. Automatic Arranging

Here after cutting pie is then automatically arrange by the help of automatic tray arranging machine.

ChenPin has practically no limits when it comes to the automatic production of pastries or pie. Whether folded, rolled, filled or sprinkled – on ChenPin make-up lines, all types of dough can be processed to create exquisite baked goods.

ChenPin offers an enormous range of accessories. You can use these to produce a comprehensive selection of pastries – very easily, with consistently high quality. The innovative engineering design enables you to switch rapidly from one pastry to the next. Stay flexible by varying your range of products using various cutters or other fillings, that will keep your customers happy and increase sales

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)