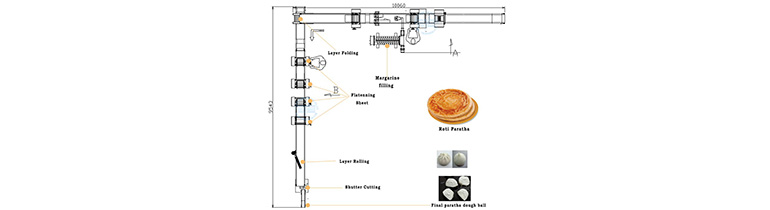

Roti canai Paratha Production Line Machine CPE-3000L

CPE-3000L Layered/ Lacha Paratha Production Line Machine

| Size | A. 10150mm (L)* 2920mm (W)* 2250mm (H) B. 9260mm (L)* 910mm (W)* 2250mm (H) |

| Electricity | 3 Phase,380V,50Hz,16kW |

| Capacity | 4,600 pcs/hrs |

| Model No. | CPE-3000L |

| Application | Dried margarine type lacha/layered paratha |

Margarine Extrude

Wrap Margarine

Stacking layers

Rolling sheet

Dough Shutter cutting

Dough by shutter cutting

Dough by vertical chopper

Place dough ball on CPE-788B for pressing & filming for desired size of paratha

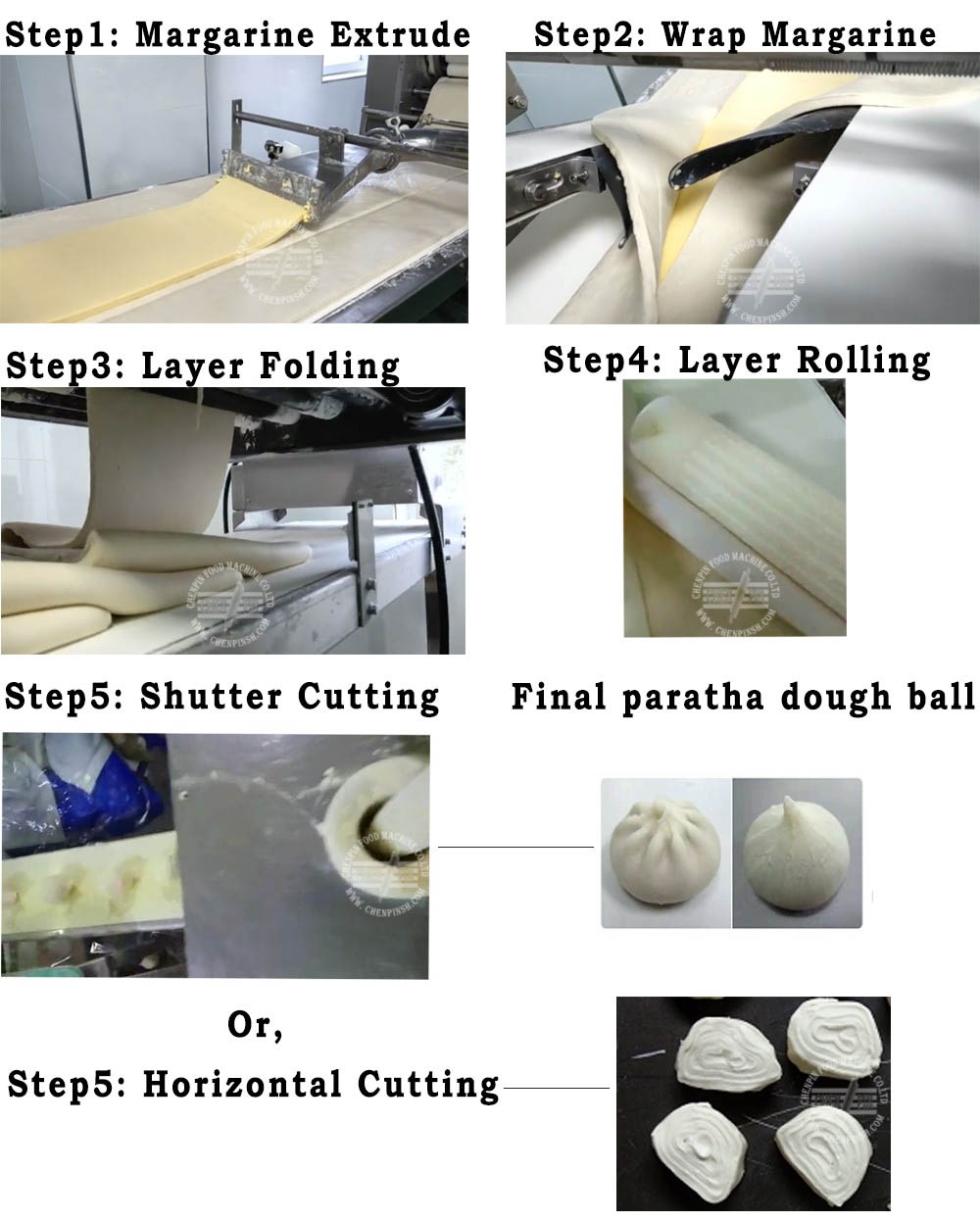

How to make layered lacha paratha? How our dough sheeting technology work?

Step 1: Margarine Extrude/Pump

The dough band former gently forms doughs of all kinds into homogeneous, stress-free dough bands without damaging the dough structure. The compact machine is mounted on castors and can be cleaned easily and quickly.

The fat pump automatically creates a continuous fat band of uniform width and thickness from blocks of margarine or butter, placing it on the dough band.

Step2: Wrap Margarine or Enclosing the fat

The folding belts then fold the dough band, completely enclosing the fat in the dough. After enclosing the fat is then transfer to dough sheeting then for layering

Step 3: Layer stacking/ Forming

Carefully and stacking of layer . This part of production is they most important part which which result create several layer inside the dough.

Step 4: Rolling

Dough is then rolled up creates more layers further. Layer at step 3 and step 4 result in managed and several layers.

Step 5: Cutting

You can select which cutter will be suitable for your product it can be modified according. We have several cutter like dough shutter cutting, Vertical cutter, etc. Required for layered paratha. Step4: you can select if you want rolling or just want pastry sheet. We can modify rolling to just the vertical cutter for pastry sheet or any other shape of pastry required.

This Production line have multifunctional application. It can produce several products like layer paratha, Puff pastry, Croissant, Just at step 4 and step 5 will need some modification.

If you want more layer like in step3 . it can be repeated two times in Model No. CPE-3000M. ChenPin dough laminating technology is more versatile it can make several kind of layered pastries.

Photo of layered lacha paratha production process

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)