Injin Layin Samarwa na Burrito CPE-650

Layin Samar da Burrito na CPE-650

| Girman | (L)18,915 * (W)1,470 * (H)2,280 mm |

| Wutar Lantarki | 380V, 3Ph, 50/60Hz, 50kW |

| Ƙarfin aiki | 3,200-8,100 (guda ɗaya/awa) |

| Lambar Samfura | CPE-650 |

| Girman latsawa | 650 * 650 mm |

| Murhu | Mataki uku |

| Sanyaya | Mataki na 9 |

| Mai tattara bayanai | Layi 2 ko layi 3 |

| Aikace-aikace | Tortilla, Chapati, Lavash, Taco, Pita |

Burrito abinci ne da ake ci a cikin abincin Mexico da Tex-Mex wanda ya ƙunshi tortilla na fulawa da aka naɗe a cikin siffar silinda mai rufewa a kusa da kayan abinci daban-daban. Wani lokaci ana gasa tortilla ɗin kaɗan ko a dafa shi da tururi don ya laushi shi, ya sa ya fi laushi, kuma a bar shi ya manne da kansa lokacin da aka naɗe shi. Sau da yawa ana cin Burritos da hannu, saboda matsewar da suke yi yana haɗa sinadaran. Sau da yawa ana cin Burritos da hannu, saboda matsewar da suke yi yana haɗa sinadaran. Ana iya yin Burritos "da ruwa", wato a rufe su da miya mai daɗi da yaji.

Yawancin burritos yanzu ana ƙera su ta hanyar hot press. Ci gaban Flatbread hot press yana ɗaya daga cikin ƙwarewar ChenPin. Burritos masu zafi suna da santsi a yanayin saman kuma suna da sauƙin birgima fiye da sauran burrito.

Domin ƙarin bayani game da hoton, danna kan hotuna masu cikakken bayani.

Tortilla

Lavash

Taco

Pita

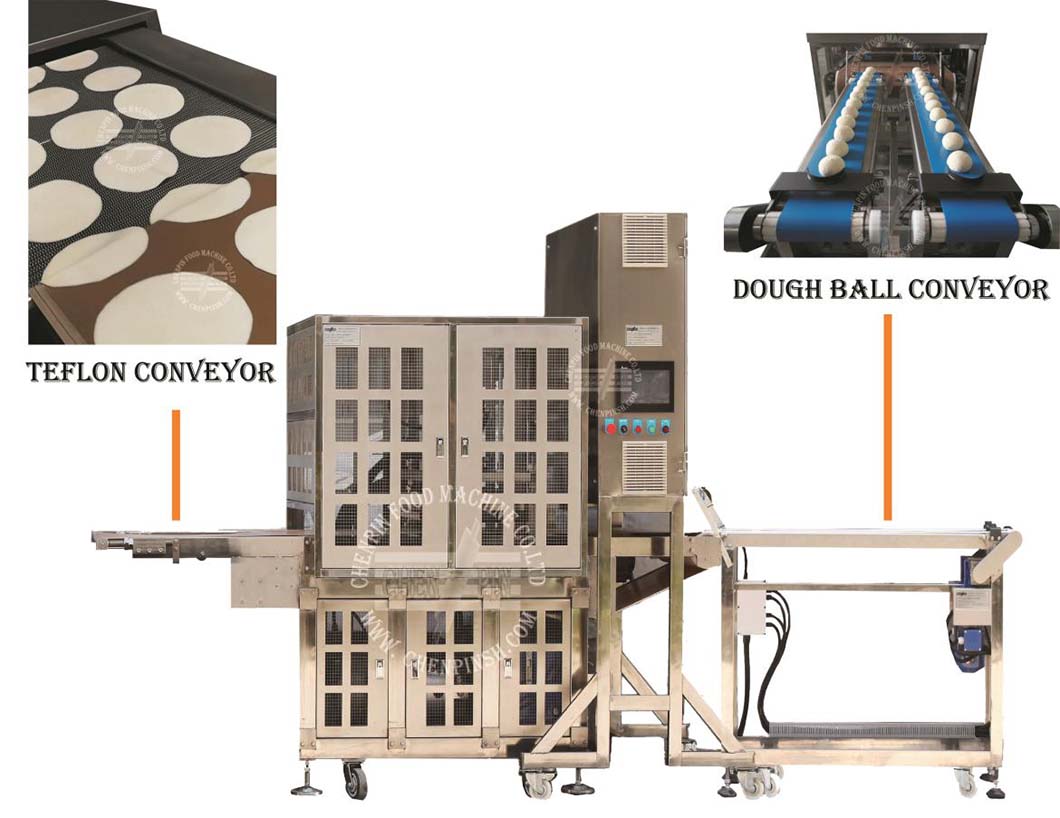

1. Burrito Hydraulic hot press

■ Haɗin gwiwa na aminci: Yana matse ƙwallon kullu daidai gwargwado ba tare da tauri da siffar ƙwallon kullu ya shafe shi ba.

■ Tsarin matsi da dumama mai yawan aiki: Yana matsi guda 4 na samfura masu inci 8-10 a lokaci guda da guda 9 na inci 6. Matsakaicin ƙarfin samarwa shine guda 1 a kowace daƙiƙa. Yana iya aiki a zagaye 15 a minti ɗaya kuma girman matsi shine 620*620mm

■ Na'urar jigilar ƙwallon kullu: Ana sarrafa tazara tsakanin ƙwallon kullu ta atomatik ta hanyar na'urori masu auna firikwensin da na'urori masu auna layuka 2 ko layuka 3.

■ Ingantaccen iko kan sanya kayan aiki a lokacin matsi don ƙara daidaiton samfurin yayin rage ɓarna.

■ Na'urorin sarrafa zafin jiki masu zaman kansu don faranti masu zafi na sama da ƙasa.

■ Fasahar hot press tana ƙara wa burrito ƙarfin juyawa.

Hoton Burrito Hydraulic hot press

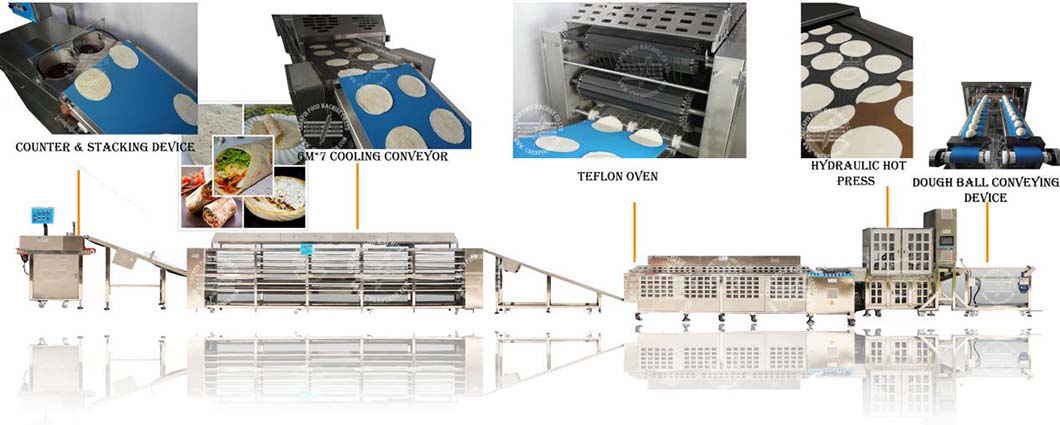

2. Murhun rami mai matakai uku/mataki

■ Kula da masu ƙona wuta da zafin gasa na sama/ƙasa. Bayan an kunna, masu ƙona wuta za su sarrafa su ta atomatik ta hanyar na'urori masu auna zafin jiki don tabbatar da yawan zafin da ake buƙata.

■ Ƙararrawar lalacewar harshen wuta: Ana iya gano lalacewar harshen wuta.

■ Girman: tanda mai tsawon mita 4.9 da kuma mataki 3 wanda zai inganta gasa burrito a ɓangarorin biyu.

■ Samar da ingantaccen aiki da daidaito a yin burodi.

■ Kula da zafin jiki mai zaman kansa. 18 Injin kunna wuta da sandar kunna wuta.

■ Daidaita harshen wuta mai zaman kansa da ƙarar iskar gas

■ Ana iya daidaita zafin jiki ta atomatik bayan an ciyar da zafin da ake buƙata.

Hoton Murhun Rami Mai Mataki Uku don Burrito

3. Tsarin sanyaya

■ Girma: Tsawon mita 6 da kuma matakin 9

■ Adadin fanfunan sanyaya jiki: Fanfunan 22

■ Belin jigilar kaya mai raga mai bakin ƙarfe 304

■ Tsarin sanyaya matakai da yawa don rage zafin abincin da aka gasa kafin a yi marufi.

■ An sanye shi da tsarin sarrafa gudu mai canzawa, na'urori masu zaman kansu, jagororin daidaitawa da kuma kula da iska.

Na'urar sanyaya Burrito

4. Mai tattara bayanai

■ Tara tarin burrito sannan a motsa burrito a cikin fayil guda ɗaya don ciyar da marufi.

■ Mai iya karanta sassan samfurin.

■ An yi amfani da tsarin iska da hopper don sarrafa motsin samfurin don tarawa yayin da yake taruwa.

Hoton na'urar Counter Stacker don Burrito

Tsarin aikin injin Roti Production na atomatik

Waya: +86 21 57674551

Waya: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)