OEM Supply Roti Press Machine - Lavash Production Line Machine CPE-800 – Chenpin

OEM Supply Roti Press Machine - Lavash Production Line Machine CPE-800 – Chenpin Detail:

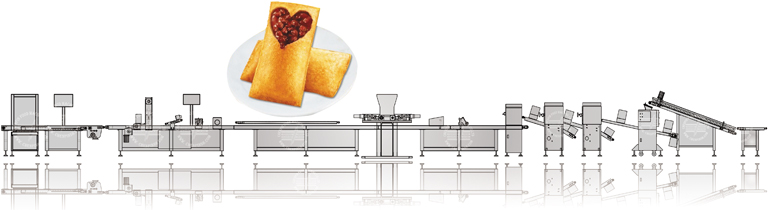

Lavash Production Line Machine CPE-800

| Size | (L)22,510mm * (W)1,820mm * (H)2,280mm |

| Electricity | 3 Phase ,380V,50Hz,80kW |

| Capacity | 3,600-8,100(pcs/hr) |

| Model No. | CPE-800 |

| Press size | 80*80 cm |

| Oven | Three level |

| Cooling | 9 level |

| Counter Stacker | 2 row or 3 row |

| Application | Tortilla, Roti, Chapati, Lavash, Burrito |

Lavash is a thin flatbread usually leavened, traditionally baked in a tandoor (tonir) or on a sajj, and common to the cuisines of South Caucasus, Western Asia, and the areas surrounding the Caspian Sea.Lavash is one of the most widespread types of bread in Armenia, Azerbaijan, Iran and Turkey.The traditional recipe can be adapted to the modern kitchen by using a griddle or wok instead of the tonir.Lavash is similar to yufka, but in Turkish cuisine lavash (lavaş) is prepared with a yeast dough while yufka is typically unleavened.

Most lavash are now manufactured by hot press or sheeter. The development of Flatbread hot press is one of the core expertise’s of ChenPin. Hot-press lavash are smoother in surface texture and more rollable than other lavash.

As time passed customer demand for more higher production result to CPE-800 Model.

■ CPE-800 Model Capacity: Press 12 pieces of 6 Inch, 9pcs of 10 Inch and 4pcs of 12 Inch running at 15 cycles per minutes.

■ Superior control of product positioning during pressing to increase product consistency while minimizing waste.

■ Independent temperature controls for both top and bottom hot plates

■ Dough ball conveyor: Distance between dough balls is automatically controlled by sensors and 4 row,3row and 3 row conveyors according to your product size.

■ Easy, faster and convenient to change Teflon conveyor belt.

■ Automatic guide system for Teflon conveyor of hot press.

■ Size: 4.9 meter long oven and 3 level which will enhance tortilla bake on both side.

■ Oven body heat resistance. Independent burner flame and volume of gas control.

■ Cooling system: Size: 6 meter long and 9 level which give more time of cooling to tortilla before packing. Equipped with variable speed control,independent drives, alignment guides and air management.

■ Accumulate stacks of lavash and move the lavash in a single file to feed packaging. Able to read the pieces of the product. Equipped with the pneumatic system and hopper are used to control the motion of the product to accumulates it while stacking.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for OEM Supply Roti Press Machine - Lavash Production Line Machine CPE-800 – Chenpin , The product will supply to all over the world, such as: Latvia, The Swiss, Finland, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)

2.png)