The global demand for consistent, high-quality layered flatbreads continues to grow, especially for products such as Lacha Paratha and Roti Canai. Within this context, the concept of a Fully Automatic Roti Canai Making Machine Fully Automatic Company reflects not only automation, but also the ability to industrialize traditional lamination techniques without sacrificing texture or structure.

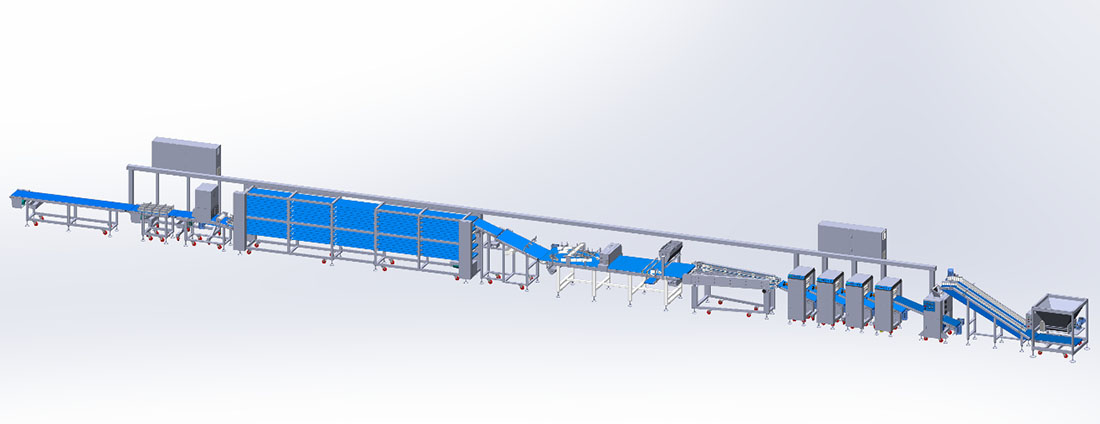

Based on this direction, CHENPIN FOOD MACHINE CO., LTD has developed its Lacha Paratha Production Line Machine as a core solution for scalable, fully automatic layered flatbread production.

From Handcrafted Technique to Industrial Precision: The Evolution of Lacha Paratha Production

Traditionally, Lacha Paratha relies on repeated stretching, oiling, rolling, and relaxing to create its rich, flaky layers. Yet manual methods depend heavily on artisan skill and lack the consistency needed for large-scale output.

CHENPIN meets this challenge by translating each handcrafted step into a controlled mechanical process—building layers progressively rather than forcing them together. Instead of compressing multiple actions into one, the production line breaks down lamination into distinct, sequenced stages:

Dough chunker → Continuous sheeting → Sheet stretching → Auto oil-bushing → Sheet dividing→Auto rolling → Relaxing&Conveying →Cutting→Rolling&Forming → Pressing & filming→ Quick freezing → Packaging

This integrated flow ensures gentle, continuous handling. Dough is sheeted under balanced tension to maintain gluten integrity; oil is applied evenly to enable clean layer separation; and scheduled relaxing phases allow stress to dissipate before further shaping.

By mirroring the logic of traditional craft with mechanical accuracy, CHENPIN's production line achieves uniform thickness, well-defined layers, and consistent quality—batch after batch. The process honors the art of hand-made paratha while delivering repeatable results, higher efficiency, and long-term production stability.

Lacha Paratha Production Line Machine: Capacity and Customization

To translate these advanced process flows into scalable commercial output, CHENPIN's Lacha Paratha Production Line Machine is available in different configurations to match production scale.

The CPE-3368 model supports capacities of 7,500–10,000 pieces per hour, making it suitable for large-scale frozen food and industrial bakery operations. Meanwhile, the CPE-3268 model, with capacities of 5,000–7,000 pieces per hour, serves medium-scale manufacturers seeking high consistency with lower footprint requirements.

Beyond standard capacity, the production line is designed for customization. Dough weight, product diameter, layer count, and relaxing structure can be adjusted according to recipe requirements. This flexibility allows manufacturers to preserve brand-specific texture profiles while maintaining stable output. To ensure continuous operation, the Lacha Paratha Production Line Machine is designed to work in coordination with CHENPIN's CP-788 series paratha pressing and filming machines. This integration enables uninterrupted transfer from pressing to film covering, reducing manual handling and preventing layer deformation.

Dough Preparation and Relaxing Control

The success of such high-speed output depends heavily on the microscopic management of the raw material. Layer integrity begins with controlled dough conditioning. In the Lacha Paratha Production Line Machine, dough is processed to achieve consistent elasticity before lamination. Multi-stage relaxing conveyors allow the dough sheet to release internal stress gradually, which is critical for preventing shrinkage and layer breakage during folding.

For example, the CPE-3368 configuration integrates extended relaxing sections of up to 6 meters with 7–9 relaxing layers, supporting stable lamination at high speed. This controlled relaxation ensures that each subsequent folding action forms clean, continuous layers rather than compressed sheets.

The defining feature of Lacha Paratha lies in its layered structure. CHENPIN replicates traditional hand-folding through synchronized rolling and folding modules that apply consistent stretching ratios across the dough sheet. Instead of aggressive compression, the system balances tension and extension, allowing oil-separated layers to form naturally. This process enables the production line to maintain uniform thickness, rich layering, and elastic texture across every piece.

Automation and System Synergy

Powering these intricate mechanical movements is a high degree of automation. Advanced control systems monitor and coordinate each stage of production, from dough conveying to pressing synchronization. Operators can manage key parameters through centralized interfaces, simplifying operation while reducing labor dependency.

At the same time, CHENPIN emphasizes customization. Production lines can be tailored to specific requirements related to paratha diameter, weight, capacity, and recipe composition. Optional functions, such as automatic scallion sprinkling, can be incorporated to expand product variety and meet regional flavor preferences. This modular customization strategy allows manufacturers to scale and diversify without replacing core equipment.

Why CHENPIN Represents a Future-Leading Approach

Ultimately, CHENPIN's competitive strength lies not in a single machine, but in its process-oriented engineering philosophy. Instead of treating each unit as an isolated function, CHENPIN designs production lines as coordinated systems that reflect real dough behavior at every stage. By analyzing gluten development, oil absorption, sheet tension, and relaxation response, the equipment is engineered to work with the dough rather than against it.

This process-driven approach enables precise control over lamination dynamics. Stretching, oiling, rolling, and relaxing are executed progressively, which reduces internal stress and improves layer stability. As a result, the production line maintains consistent performance even at high operating speeds, without sacrificing flakiness or structural clarity.

Moreover, CHENPIN emphasizes equipment coordination and timing accuracy across the entire line. Conveying speed, roller pressure, and relaxing duration are synchronized through centralized control logic, allowing each process to support the next. This coordination minimizes deformation, lowers scrap rates, and enhances repeatability during extended production cycles.

Conclusion

As global demand for layered flatbreads continues to expand, manufacturers increasingly require solutions that combine automation with craftsmanship-level quality. CHENPIN's Lacha Paratha Production Line Machine demonstrates how advanced process design and mechanical precision can preserve traditional characteristics while enabling industrial scalability.

Through controlled sheeting, precise oiling and rolling, structured relaxing, and seamless automation, CHENPIN provides a future-ready foundation for reliable and high-quality flatbread production.

For more information about CHENPIN's Lacha Paratha Production Line Machine and automated flatbread solutions, please visit: https://www.chenpinmachine.com/.

Post time: Jan-30-2026

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)