As global consumption of desserts grows and food manufacturers increasingly prioritize consistency, efficiency, and food safety, the role of automated bakery solutions has shifted from optional to essential. In this changing landscape, the Future Leading Automatic Egg Tart Production Line Company concept highlights systems capable of reproducing delicate pastry products with industrial precision. An automatic egg tart production line integrates dough forming, cup shaping, filling coordination, baking scheduling, and conveying into a continuous process that supports both traditional taste and scalable output. Within this context, CHENPIN FOOD MACHINE CO., LTD (CHENPIN) stands out, not merely as an equipment supplier, but as a company with differentiated technical depth in key egg tart production stages and proven integration capability for complex pastry processes.

The Evolving Role of Automated Egg Tart Production

Egg tarts, a dessert with origins in both Portuguese and East Asian bakery traditions, have moved far beyond local bakery counters. They now feature prominently in global retail, frozen dessert offerings, and foodservice menus. Unlike simpler baked goods, egg tarts require precise handling of laminated pastry dough, uniform shaping of tart shells, and accurate portioning of liquid custard filling. These requirements present challenges in manual operations, where variability in thickness, shape, and baking quality can lead to inconsistencies in product appearance and texture. As a result, manufacturers increasingly seek solutions that standardize these steps without compromising sensory qualities. CHENPIN's automatic egg tart production line targets these high-impact stages, providing an automation backbone that supports stable, repeatable results at industrial volumes.

What Sets CHENPIN Apart from General Automation Suppliers

General bakery automation suppliers often focus on individual machines for mixing, baking, or cooling. By contrast, CHENPIN concentrates on integrated process sequences that address the specific challenges of egg tart production, particularly in laminated pastry handling and shell forming.

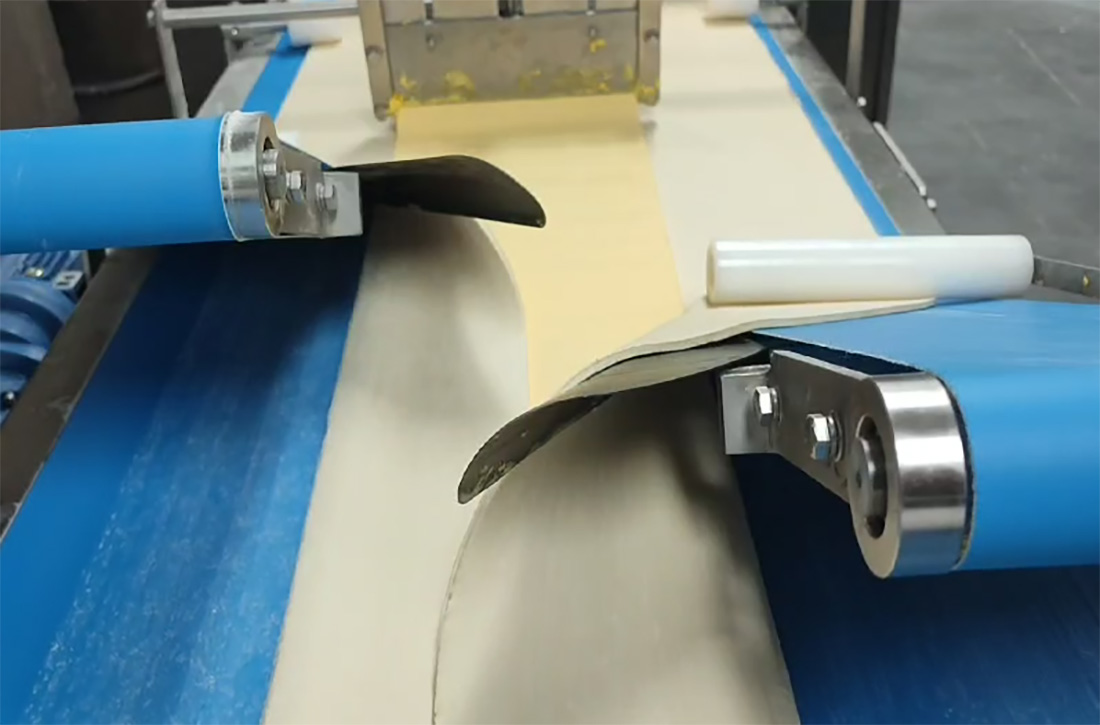

CHENPIN applies laminated dough technology originally developed for puff pastry to egg tart crust formation. This includes controlled margarine extrusion and wrapping, followed by repeated transverse layering to build stable, multi-level pastry structures. These steps directly influence shell crispness, layer separation, and forming stability—areas where standard forming machines typically struggle.

Unlike basic systems that operate within narrow size limits, CHENPIN's egg tart production line supports multiple tart shell diameters and different laminated thickness profiles. Adjustable forming and sheeting parameters allow operators to fine-tune pastry thickness and layer structure without mechanical redesign. This flexibility is essential when producing egg tarts for different markets or brand specifications.

At the technical core, CHENPIN focuses on how laminated dough behaves during pressing, layering, and transfer. Equipment designs emphasize controlled deformation and gentle handling, reducing layer damage before filling and baking. As a result, the production line delivers consistency not through rigid standardization, but through precise control of laminated dough mechanics—an approach that distinguishes CHENPIN from general-purpose automation suppliers.

Technical Focus: Key Stages in Egg Tart Automation

The automatic egg tart production line typically includes a sequence of specialized modules, each addressing a technical challenge that affects final product quality. For example, CHENPIN's equipment supports controlled dough sheet handling with precise thickness control, followed by cup forming with repeatable shape and wall uniformity. Conveyors then move formed shells into cooling zones that synchronize, maintaining continuous flow. By linking these stages through coordinated control systems, the line minimizes manual handling—a known source of inconsistency—and supports stable batch quality over time.

This coordination extends to flexibility for different tart shell diameters and pastry styles. In practice, manufacturers can adjust forming parameters and tooling to produce smaller or larger shell sizes and to accommodate variations in pastry thickness or layering patterns.CHENPIN's egg tart production line is designed to be flexible, allowing it to quicklyadjust its capacity in response to market trends and meet thediverse needs of the market.

Operational Advantages in Practice

Beyond technical differentiation, automatic production lines influence broader operational outcomes. Automated forming and shaping reduce reliance on skilled labor, often a bottleneck in artisan pastry production. This reduction in labor dependency correlates with improved hygiene, as fewer manual contacts reduce contamination risk. Additionally, manufacturers often experience more predictable output, as automated control over pressing and forming ensures consistent portion size and shell integrity. For facilities with high throughput demands, these factors contribute to reduced waste, streamlined workflows, and clearer production planning.

Manufacturers using CHENPIN's egg tart automation solutions report smoother transitions between dough handling and baking stages. This is significant because variability at early forming steps can propagate through to final baking, affecting texture and appearance. Coordinated automation mitigates this risk, leading to products that meet visual and sensory expectations consistently.

CHENPIN's Technical Strength in Egg Tart Pastry Formation

What differentiates CHENPIN in the egg tart production line segment lies primarily in its handling of laminated puff pastry, a stage that directly determines shell structure, baking performance, and visual quality. Rather than treating lamination as a secondary process, CHENPIN places it at the core of its system design.

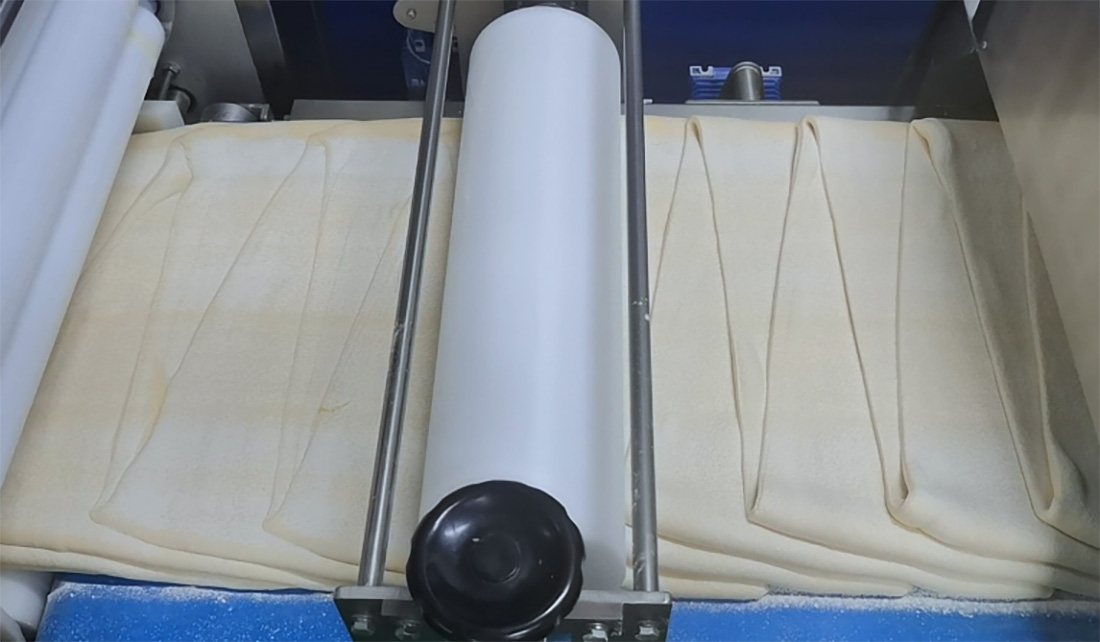

The production line integrates automatic margarine extrusion and wrapping, allowing fat to be evenly enclosed within the dough sheet under controlled conditions. This step replaces manual oil application with a standardized process, reducing variability in lamination and supporting consistent lift during baking. Dough thickness is refined progressively through multiple sheeting stages and side calibrators, while excess material is automatically collected and recycled, improving material efficiency without interrupting production flow.

A key technical feature is CHENPIN's transverse dough laying system. Instead of relying on conventional longitudinal folding, the dough ribbon is spread and layered horizontally using dedicated laminators and roller spreaders. This approach enables finer adjustment of layer count and thickness while maintaining dough integrity at industrial speeds. The layering process is repeated in sequence, forming stable multi-layer structures that remain uniform even in smaller-diameter tart shells.

Because these lamination modules operate within a fully automatic line, operators gain easier access for cleaning and maintenance. All product-contact surfaces are manufactured from SUS 304 stainless steel, supporting hygiene standards required for export-oriented and high-volume facilities.

This lamination technology is not limited to egg tarts alone. The same system can be configured for croissants, puff pastry sheets, layered paratha, and related products, demonstrating CHENPIN's broader product range in multi-layer dough processing rather than single-product automation.

When Automated Egg Tart Lines Are Most Relevant

Introducing an automatic egg tart production line is most appropriate when product demand, quality expectations, and operational constraints intersect. Companies that already operate at moderate volumes (such as several thousand pieces per day) and encounter inconsistent product quality are prime candidates. Automation becomes even more relevant when expanding into frozen or retail markets, where appearance, texture, and shelf performance carry commercial risk if not consistently managed.

Conversely, very early stage producers with low production volumes or those still defining product specifications may not find full automation cost-effective. In such cases, automation adoption is most rational once manual or semi-automatic processes begin to limit capacity, increase variability, or fail to meet regulatory or customer standards.

Conclusion: Aligning Technology and Production Strategy

In assessing whether CHENPIN qualifies as a company worth consideration for automatic egg tart production automation, professionals should note two distinct strengths. First, CHENPIN's integration capability—linking dough handling, shaping, and downstream processing—addresses the specific demands of laminated pastry production beyond what generic automation suppliers typically offer. Second, flexibility in supporting variations in shell diameter, layer count, and downstream equipment integration makes its solutions adaptable to diverse production environments. These capabilities support stable output and operational clarity in higher-demand settings.

Manufacturers contemplating automation should weigh production volume, product complexity, and long-term quality objectives. When quality control becomes a limiting factor or when market scale outpaces manual capacity, automated egg tart production lines offer a rational and strategic path forward. To learn more about CHENPIN's automated machinery suitable for egg tart and related pastry production, visit https://www.chenpinmachine.com/.

Post time: Jan-17-2026

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)