In response to expanding global demand for automated flatbread and wrap-style products, the Global Leading Automatic Tortilla Production Line is setting new benchmarks in food manufacturing efficiency and consistency. This state-of-the-art solution integrates intelligent control systems, hot pressing, baking, and advanced cooling to, continuous production of tortillas, taco, lavash, and other flatbread formats with minimal manual intervention. At the forefront of these innovations stands CHENPIN FOOD MACHINE CO., LTD (CHENPIN), whose engineering expertise and decade-plus dedication to dough processing technologies continue to define performance standards in industrial tortilla manufacturing.

Transforming Food Production: Market Trends and Industry Dynamics

The global food processing industry is accelerating its shift toward automation, driven by rising labor costs, tighter food safety regulations, and the rapid expansion of international foodservice chains. At the same time, flatbreads have moved from regional staples to global mainstream products. Tortillas, wraps, pita, and now anchor menus across quick-service restaurants, frozen food brands, and retail bakeries.

As a result, manufacturers increasingly require production systems that can sustain high throughput while preserving product uniformity. Manual or semi-automatic lines struggle to meet this dual requirement. Automated tortilla production lines therefore play a strategic role in capacity expansion and quality stabilization.

In this context, tortilla production has become one of the most competitive segments in dough-based processing. Demand fluctuates across regions and seasons, which means manufacturers must deploy flexible systems that can shift between medium-scale and ultra-high-volume production without structural redesign.

CHENPIN's Heritage and Engineering Foundation

Founded in 2010 and built on more than three decades of accumulated engineering experience in dough processing, CHENPIN FOOD MACHINE CO., LTD has focused its research on the most technically sensitive stages of flatbread production: dough handling, pressing stability, thermal baking uniformity, and continuous cooling control.

Unlike equipment suppliers that assemble generic modules, CHENPIN develops integrated line architectures. Mechanical structure, control logic, and thermal design are engineered as a single system. This systems-level approach explains why CHENPIN lines maintain stable product geometry at industrial speeds while many competitors struggle with thickness deviation, blistering inconsistency, and moisture imbalance.

This technical orientation has resulted in multiple patented mechanisms across dough forming, pressing synchronization, and modular oven control. These innovations form the foundation of CHENPIN's global leadership in automatic tortilla production.

Core Technology Inside the Global Leading Automatic Tortilla Production Line

At the center of CHENPIN's Global Leading Automatic Tortilla Production Line lies a production logic built around continuous stability rather than isolated speed. The line integrates four critical stages: dough dividing and conveying, synchronized pressing, multi-zone baking, and controlled cooling and stacking.

Precision Dough Feeding and Forming Stability

CHENPIN production lines apply servo-driven dough conveying systems that maintain consistent spacing and weight distribution before pressing. This design minimizes deformation at high throughput and reduces downstream correction. In high-capacity configurations such as the CPE-1100,CPE-950 and CPE-800 series, stable dough alignment remains consistent even when output exceeds 14,000 pieces per hour. This stability is essential for industrial buyers supplying global QSR chains, where dimensional tolerance directly affects downstream filling and packaging automation.

For mid-capacity plants, models such as the CPE-650 and CPE-450 apply the same forming principles on a compact footprint. This unified technical platform across capacities allows manufacturers to scale production without retraining process logic.

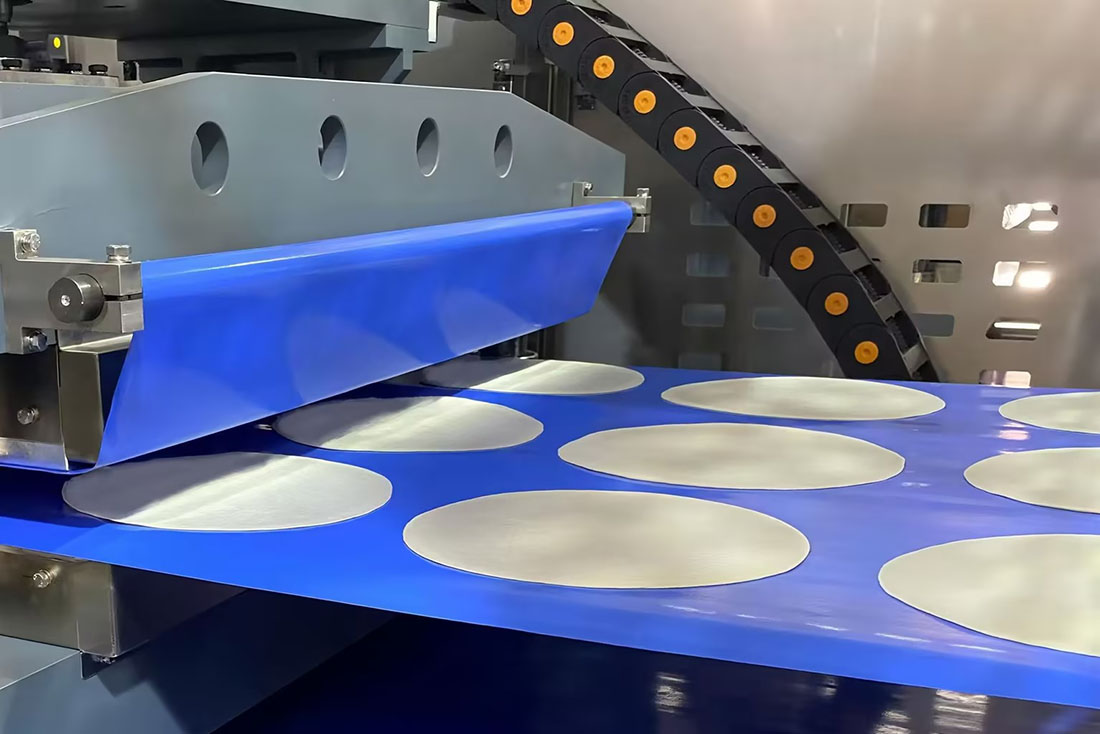

High-Precision Pressing and Thickness Control

Pressing represents the most decisive stage in tortilla quality formation. CHENPIN lines employ synchronized dual-surface pressing systems that maintain parallelism throughout the compression cycle. This design prevents center-thick and edge-thin defects commonly found in conventional pressing structures.

Through real-time thickness calibration, operators can adjust tortilla diameter and thickness without mechanical replacement. This flexibility enables a single line to switch efficiently between 6-inch wraps, 8-inch tortillas, 10-inch tortillas and 12-inch flatbreads, a capability increasingly valued by co-manufacturers serving multiple brand clients.

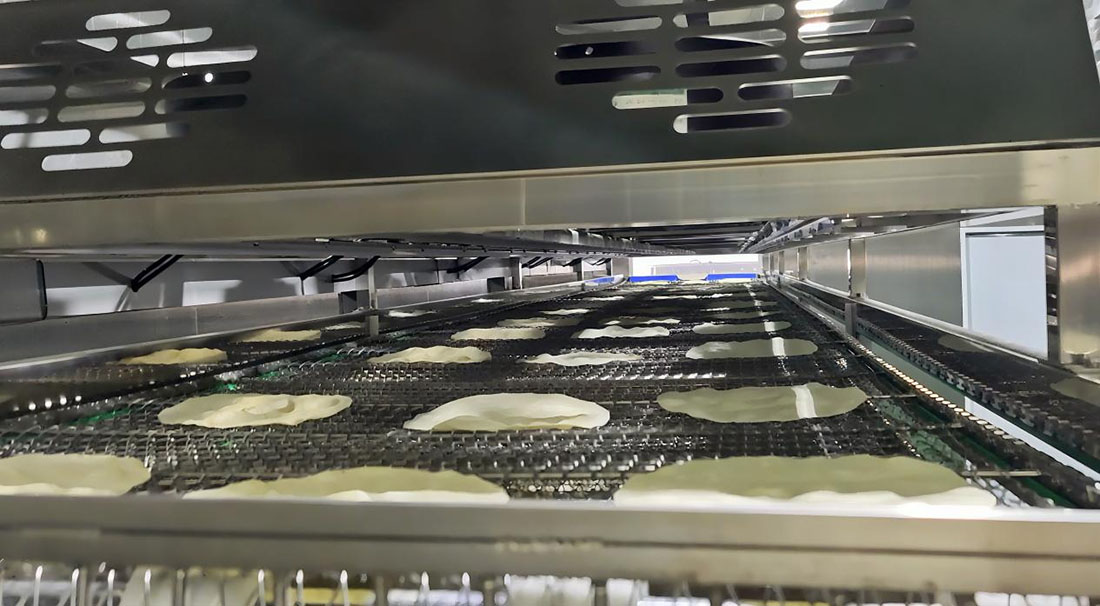

Three-Tiered Oven with Precision Thermal Control

CHENPIN's production system utilizes a three-tiered oven architecture, with each tier featuring independent and precise temperature regulation. This multi-layer design enables targeted heat application for different baking phases.

The structure ensures uniform baking, reduces cracking, and enhances product stability. By separating heat zones vertically, CHENPIN maintains consistent quality and color even at high production speeds.

Intelligent Cooling and Product Handling

After baking, CHENPIN integrates variable-speed cooling conveyors that stabilize internal moisture before stacking. Instead of relying on fixed airflow parameters, the system adjusts cooling time according to line speed and product thickness.

This control logic prevents condensation inside packaging and minimizes post-bake deformation. As a result, manufacturers experience lower rejection rates in automated packing lines, particularly in frozen tortilla and export-oriented operations.

Scalable Line Architecture Across Global Markets

One defining strength of CHENPIN lies in its scalable product architecture. The CPE-450 and CPE-650 platforms serve emerging regional producers seeking automation without overcapacity. Meanwhile, the CPE-800, CPE-950 and CPE-1100 series support multinational food groups operating continuous, multi-shift production environments.

Crucially, all models share the same engineering DNA. Control interfaces, mechanical logic, and maintenance structure remain consistent across the product range. This standardization allows manufacturers to expand capacity without operational disruption, an advantage that significantly reduces long-term integration costs.

Few global suppliers offer such technical continuity across capacity tiers, reinforcing CHENPIN's position as a system architect rather than a component vendor.

CHENPIN's Broader Automated Flatbread and Pastry Ecosystem

Beyond tortillas, CHENPIN applies the same engineering logic to laminated pastry lines, paratha and roti paratha, pizza production lines, and ciabatta and panini bread solutions. This cross-category expertise strengthens tortilla line development, as innovations in lamination stability and thermal profiling migrate across product platforms.

This horizontal technology transfer creates a continuous innovation loop that isolated tortilla machine manufacturers cannot replicate. It further explains CHENPIN's sustained technological leadership across multiple dough-based food categories.

Customer Outcomes and Operational Impact

Global manufacturers operating CHENPIN tortilla production lines consistently report improvements in yield stability, line uptime, and product uniformity. Large food groups benefit from reduced operator dependency, while medium-scale producers gain access to industrial-grade automation without excessive system complexity.

Equally important, CHENPIN's customer-centric service models integrates process consultation, installation engineering, and lifecycle service. This structure ensures that production performance remains stable long after commissioning, a factor that directly influences return on investment.

Outlook: Intelligent Production as a Competitive Necessity

As global consumption of tortillas and flatbreads continues to expand, production efficiency alone no longer defines competitiveness. Manufacturers must also deliver consistency across regions, brands, and regulatory environments.

The Global Leading Automatic Tortilla Production Line represents a mature response to this challenge. Through integrated mechanical design, digital control logic, and scalable architecture, CHENPIN provides manufacturers with a production platform capable of evolving alongside market demand.

In an industry where reliability defines long-term partnerships, CHENPIN's system-level engineering approach positions the company not only as an equipment supplier, but as a long-term technology partner for industrial flatbread production worldwide.

To learn more about CHENPIN's solutions, product specifications, and how they can support your production objectives, visit https://www.chenpinmachine.com/.

Post time: Jan-30-2026

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)