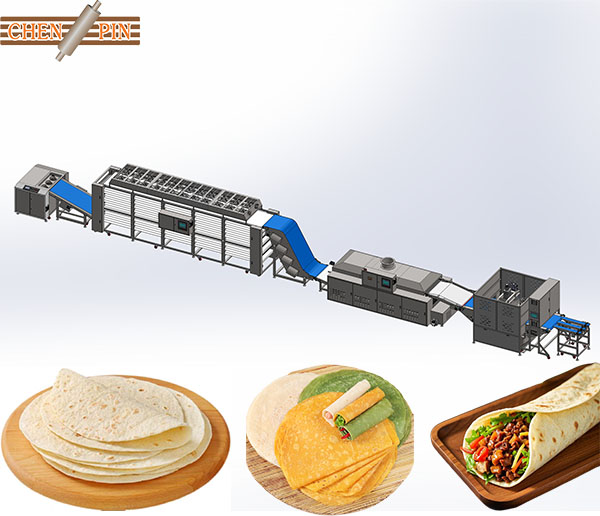

In today's fast-paced food production environment, efficiency, consistency, and scalability have become decisive factors for manufacturers serving tortilla and burrito markets. The High Quality Tortilla Burrito Forming Line Company concept reflects a shift toward integrated automation systems that deliver stable output while supporting long-term capacity growth. Instead of relying on fragmented equipment or labor-intensive processes, many producers now evaluate forming lines as complete production solutions. Within this context, CHENPIN FOOD MACHINE CO., LTD (CHENPIN) has developed tortilla/burrito production line machinery designed to support reliable integration into industrial bakery operations.

Why Integration Matters More Than Individual Speed

Increasing output does not depend solely on machine speed. In practice, stable production depends on how well each stage of the forming line connects with the next. Poor synchronization between pressing, baking, cooling, and stacking often limits actual throughput.

CHENPIN's tortilla/burrito production lines address this challenge by structuring the workflow as a continuous system. Dough portions move from hot pressing to baking, cooling, and stacking without unnecessary stops. As a result, product flow remains predictable, which helps operators maintain consistent daily output rather than short bursts of peak capacity.

Moreover, integrated forming lines reduce manual handling. This not only improves hygiene control but also stabilizes product quality across long production runs.

Core Process of CHENPIN Tortilla/Burrito Production Line

CHENPIN tortilla/burrito production lines encompass models such as CPE-450, CPE-650, CPE-800, CPE-950, and CPE-1100. The core process flow is as follows:

The production process begins with dough balls entering the hot press unit. This unit is equipped with independently temperature-controlled upper and lower heating plates, allowing flexible adaptation to different dough formulations and thickness requirements for precise forming.

Subsequently, the formed dough sheets are directly conveyed to a multi-layer baking oven. During baking, the oven uniformly heats both sides of the product. This enhances the surface toughness of the wrap while preserving its internal flexibility, facilitating further processing.

After baking, the product enters the cooling conveyor section. This stage employs stable and continuous cooling to effectively regulate product moisture and set the shape, preparing it for subsequent stacking.

Finally, via an automatic counting and stacking system, the tortilla/burrito wraps are neatly output in specified quantities, ready for direct connection to packaging, freezing, or further processing operations. The conveyor system throughout the entire line maintains precise spacing, effectively preventing product deformation and misalignment.

Ensuring Consistency in Large-Scale Production through Equipment Design

Production consistency is a key consideration for manufacturers when selecting automated forming lines. CHENPIN tortilla/burrito production lines rely on highly repeatable mechanical control, minimizing human intervention to ensure stable output.

The hot press unit applies uniform pressure to the dough, guaranteeing consistency in diameter and thickness across batches. Combined with sensor-based positioning technology, it achieves precise feeding and spacing control, significantly reducing quality variations common in manual or semi-automatic production.

The baking and cooling sections also adhere to standardized design. Through controlled baking profiles and sufficient cooling paths, the wrap structure becomes more stable. The final product maintains flexibility while being less prone to tearing during handling or filling operations.

How to Choose the Right Production Line Configuration

To meet different capacity needs and factory conditions, CHENPIN offers a diverse range of tortilla/burrito production line models for precise user matching:

CPE-450: Suitable for entry-level production with limited space or modest capacity requirements.

CPE-650: Achieves higher output within a compact layout, balancing efficiency and footprint.

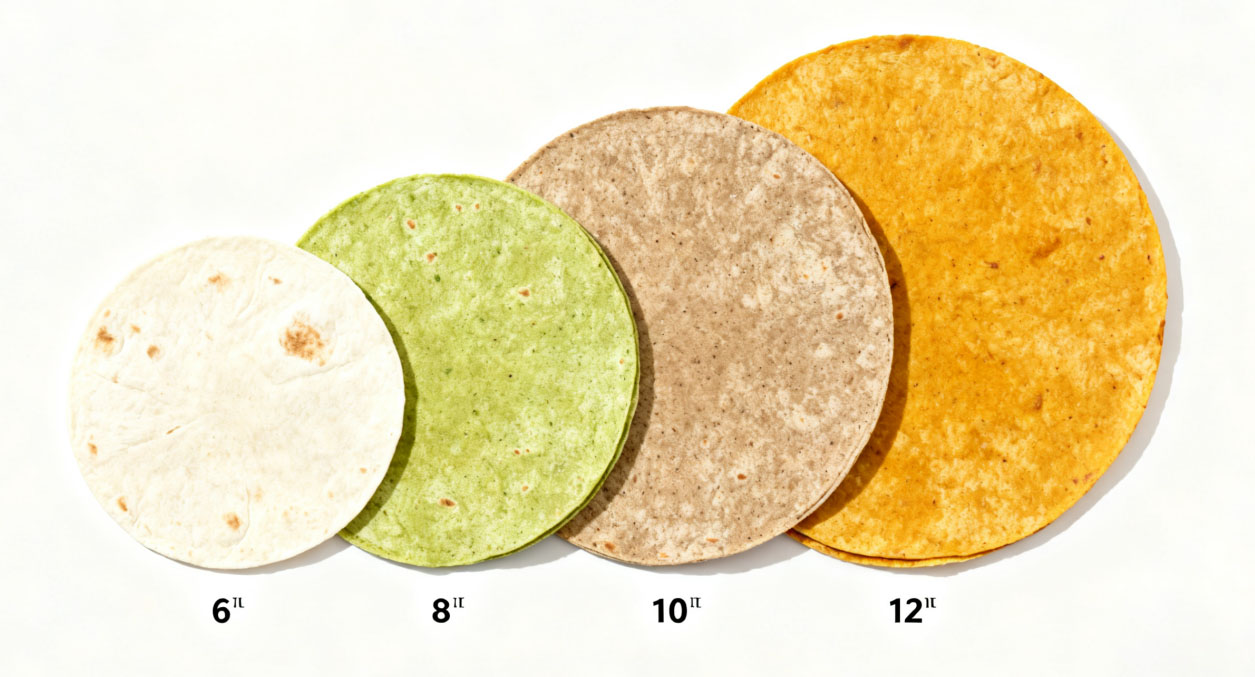

CPE-800: Delivers stable, high-volume output, with optimized production efficiency specifically for 8-inch wraps, capable of producing up to 8,100 pieces per hour.

CPE-950: In standard production of 6-12 inch wraps, it focuses on 6-inch wrap production, achieving a capacity of up to 14,000 pieces per hour, offering significant targeted output advantages.

CPE-1100: In the production of 6-12 inch wraps, it is better suited for 12-inch large wraps. With a wider pressing width and a high output of up to 7,500 pieces per hour, it meets large-scale production demands.

This product series enables production units to flexibly select the most suitable model based on their specific product specifications and capacity goals, facilitating efficient investment and production expansion.

Practical Integration Considerations for Factories

Successful integration depends on more than equipment delivery. Manufacturers often achieve better results when they evaluate upstream and downstream processes together.

For example, dough preparation capacity should match press throughput. Likewise, packaging or freezing equipment must handle the steady output from the stacking system. When production speeds remain balanced across stages, downtime decreases and labor efficiency improves.

Maintenance access also plays a role. CHENPIN's line layouts allow operators to clean and service key components without dismantling the entire system. This supports daily hygiene routines and reduces unplanned stoppages.

Manufacturing Capability and Technical Foundation

CHENPIN FOOD MACHINE CO., LTD was established in 2010, building on a technical team with more than 30 years of experience in food equipment development. From the outset, the company has concentrated on automated solutions for dough-based and flatbread products, an area that requires a high level of mechanical precision and process stability. Its equipment portfolio covers core production stages such as pressing, baking, conveying, cooling, and stacking, allowing systems to function as complete and coordinated production lines rather than isolated machines.

Beyond product design, CHENPIN has invested consistently in its manufacturing infrastructure. The company operates dedicated production facilities that support in-house machining, assembly, and testing. This manufacturing control enables tighter tolerances, stable component quality, and repeatable equipment performance across different production batches. Before delivery, machines undergo functional testing to ensure alignment with specified process requirements and operational conditions.

In addition, CHENPIN manages research and development, manufacturing, and after-sales support within a unified organizational structure. This vertical integration shortens communication cycles between engineering, production, and service teams. Feedback from installation sites and long-term customer operation feeds directly into equipment optimization and design refinement. As a result, product updates tend to focus on practical improvements such as ease of operation, maintenance accessibility, and long-duration reliability.

Over time, this development approach has supported the creation of machine designs suited for continuous industrial use. Instead of prioritizing short-term performance gains, CHENPIN emphasizes mechanical durability, process consistency, and adaptability to different factory environments. This technical foundation allows manufacturers to integrate CHENPIN equipment as part of long-term production planning, rather than as a short-term capacity fix.

Post time: Jan-08-2026

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)