As global demand for ethnic flatbread continues to expand, paratha has moved from regional staple to mainstream commercial product. This shift places new pressure on manufacturers to balance traditional texture with industrial consistency. In this context, the High Quality Paratha Pressing Machine From China has become a focal point for producers evaluating automation strategies. Rather than replacing entire production lines, paratha pressing and filming machines address one of the most critical and difficult steps in the process: forming uniform, layered dough sheets at scale. CHENPIN FOOD MACHINE CO., LTD (CHENPIN) has developed several dedicated models to meet this need, offering manufacturers clear options depending on production volume, product type, and factory layout.

Market Context: Why Pressing and Lamination Are More Critical Than Ever

Paratha production places unique demands on equipment. Unlike single-layer flatbreads, paratha relies on repeated fat layering and precise pressing to achieve its signature flaky texture. Traditional manual methods heavily depend on skilled labor and struggle to maintain consistency. As production scales up, inconsistencies in thickness, layer distribution, and size often become bottlenecks—even more so than mixing or packaging stages.

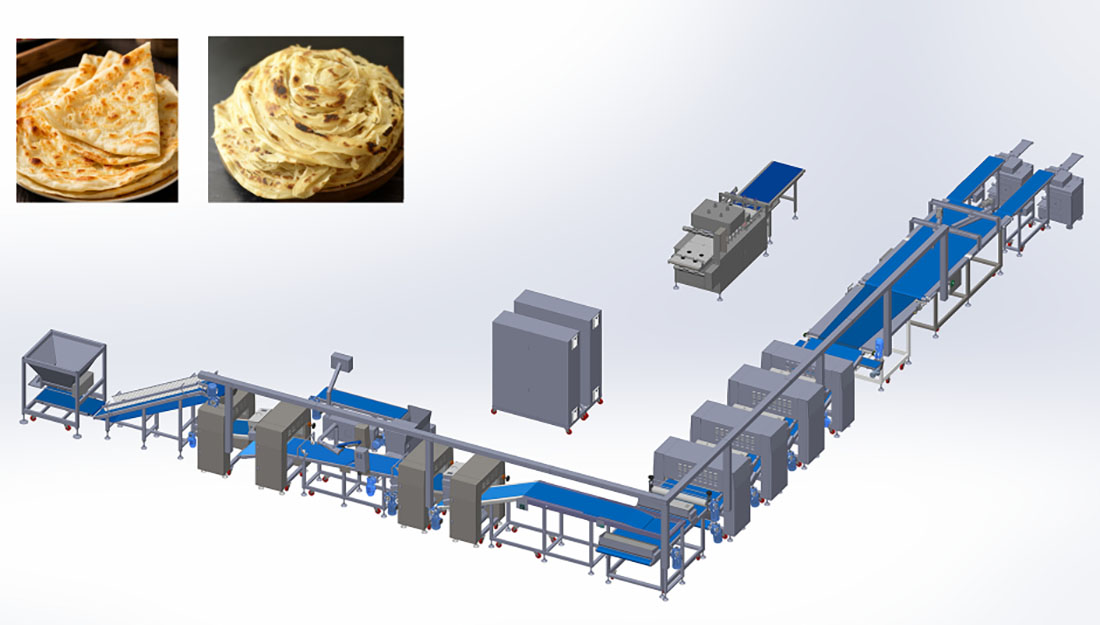

That is why more and more manufacturers are turning to professional food machinery production line suppliers—such as CHENPIN's Roti Canai/Paratha Production Line CPE-3000LE—to ensure product uniformity and large-scale efficiency.

How to Create Layered Lacha Paratha: Inside CHENPIN's Dough Lamination Technology

Designed to replicate the artisanal quality of handmade layered pastries, this system streamulates the complete traditional lamination process—from initial dough sheeting and precise margarine wrapping, through automated folding and rolling, all the way to final shaping. It captures the delicate, multi‑textured quality of hand‑crafted products while ensuring consistency at scale.

Fully Automated Operation

The line significantly reduces reliance on skilled labor through integrated automation, lowering operational costs while boosting output and repeatability. This allows manufacturers to scale production without compromising on the layered structure or flaky texture that define premium pastry products.

Consistent Quality, Scalable Output

By combining precision engineering with adaptable design, this solution delivers uniform high‑quality layering across batches, making it ideal for both dedicated production and mixed‑product operations. Whether aiming for artisan‑style results or high‑volume output, the system provides a reliable, efficient foundation for superior pastry manufacturing.

Key Pressing Models and Their Practical Differences

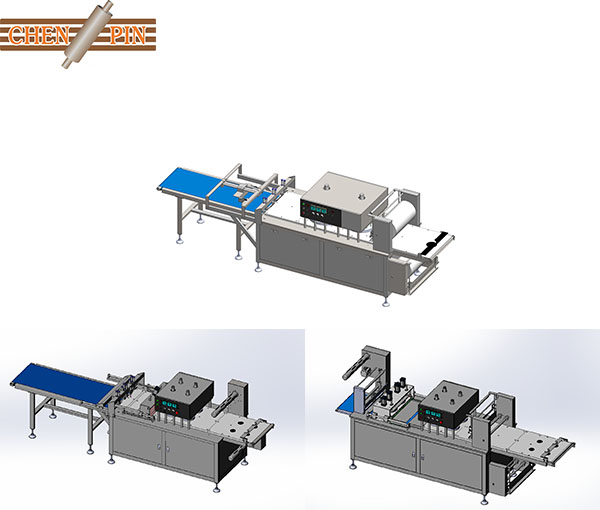

To complement the production line, CHENPIN offers a dedicated film-pressing machine series, available in various configurations to match different capacity and operational needs:

CHENPIN CPE-788 Series Film-Pressing Machine can be configured in single, double, or quadruple-row layouts depending on dough piece diameter (ranging from 100–520 mm). Highly adaptable and capable, it delivers outputs of up to 6,000 pieces per hour.

All machines in the series can be customized according to requirements—including electrical specifications, product dimensions, and production capacity—ensuring seamless integration with the production line for efficient, standardized output.

CHENPIN's Technical Foundation in Paratha Pressing

Founded in 2010, CHENPIN FOOD MACHINE CO., LTD builds on a technical team with more than 30 years of experience in food equipment development. The company focuses on automated solutions for dough-based and flatbread products, with particular strength in pressing, conveying, and layered pastry handling. By managing research and development, manufacturing, and after-sales support internally, CHENPIN maintains direct feedback loops between customer use cases and equipment refinement. Over time, this structure has resulted in machine designs optimized for continuous industrial operation rather than short-term output gains.

When Introducing a Pressing Machine Makes Sense

A paratha pressing and filming machine delivers the most value at a specific stage of growth. Companies experiencing frequent quality complaints, inconsistent product size, or rising labor dependency often reach this point first. Similarly, manufacturers preparing to enter frozen or private-label retail markets typically require tighter dimensional control than manual processes allow.

In contrast, very early-stage producers with limited volumes may not benefit immediately. Pressing machines achieve their return when production runs become long enough for consistency and labor savings to outweigh capital cost.

Conclusion: Matching Equipment to Production Reality

Paratha pressing machines do not replace craftsmanship; they stabilize it at scale. For manufacturers seeking predictable output, controlled layering, and smoother downstream processing, CHENPIN's range of paratha pressing and filming machines offers clearly differentiated options. The decision to invest should align with production volume, product range, and long-term market goals rather than short-term capacity targets alone.

Companies best positioned to consider this equipment today include mid- to large-scale bakeries, frozen food processors, and producers preparing for export or private-label supply. At this stage, targeted automation often delivers faster returns than full line replacement. To review technical specifications and configuration options in detail, visit https://www.chenpinmachine.com/.

Post time: Jan-08-2026

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)