In the previous two issues, we introduced the customized production lines of Chenpin: the Panini bread production line, the fruit pie production line, as well as the Chinese hamburger bun and French baguette production line, experiencing the inclusiveness and innovation of Chenpin's production lines. This issue, let's take a look at the world of the richly flavored "curry pie" and the simple yet hearty "scallion pancake"! Witness how Chenpin food machinery endows traditional delicacies with new vitality through mechanization!

Curry puff production line: A single layer of flaky pastry, myriad flavors

In the highly competitive food market, the curry pie has gained popularity among consumers due to its unique charm of "crispy crust enclosing myriad flavors". Chenpin Machinery has precisely grasped the market demands and meticulously designed the production line for curry pies.

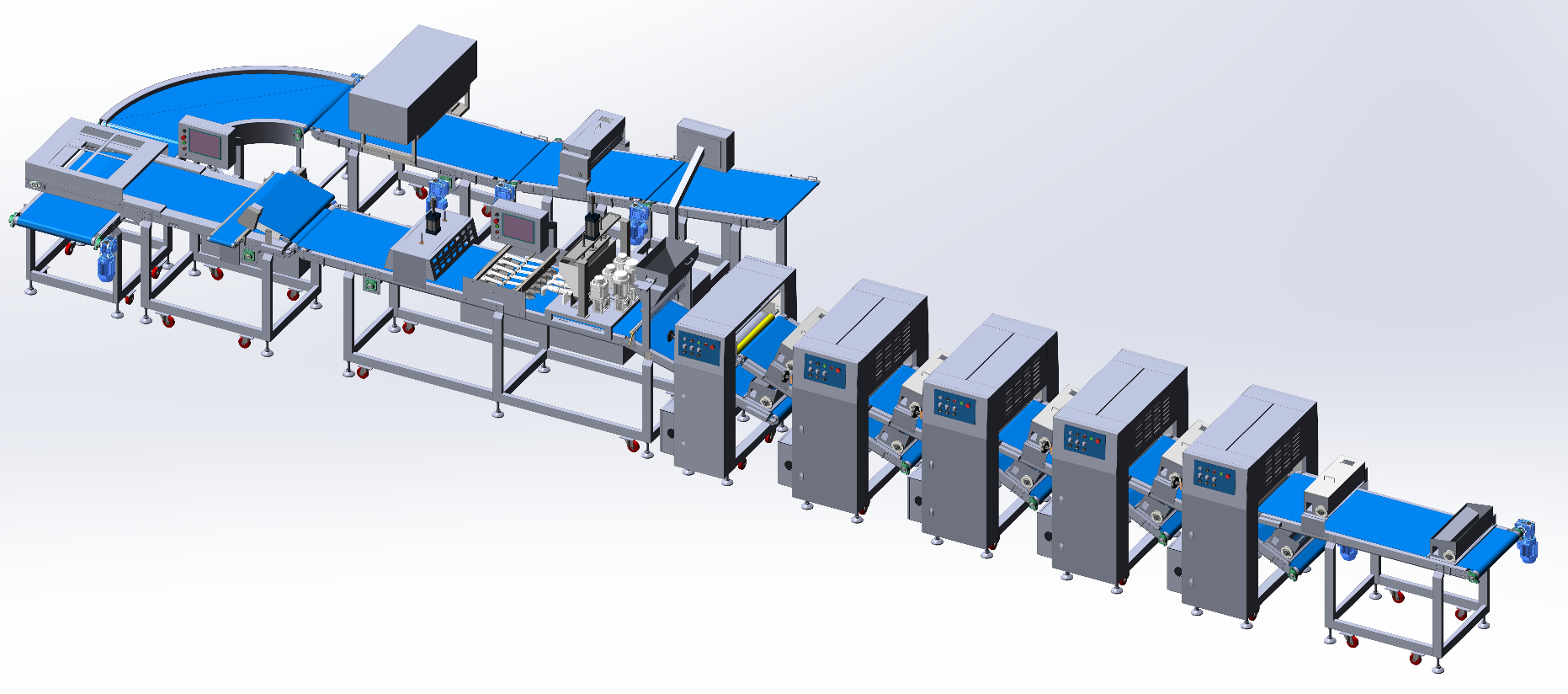

The Chenpin Curry Pie production line has an hourly capacity of 3,600 units, meeting the batch production requirements of large-scale food enterprises. Precise process: from the stretching and pressing of the dough to thinning, precise filling, mold shaping, egg wash application, and automatic plate placement, every step has been meticulously designed and repeatedly tested to ensure that each curry pie has a perfect shape and taste, perfectly reproducing the exquisite craftsmanship of hand-made production.

In addition, the equipment also features flexible customization capabilities. It allows for the free adjustment of filling ratios and enables the customization of product specifications as desired, easily meeting the diverse demands of different regional markets.

Scallion pancake forming machine: Classic and delicious

Scallion pancake, as a classic Chinese pastry, holds countless people's childhood memories and taste preferences. However, traditional manual production faces issues such as low efficiency and difficult quality control. Chenpin Machinery has launched a customized sesame seed fried bread forming machine, providing a perfect solution to this problem.

With an efficient production capacity of 5,200 sheets per hour, it is equivalent to the work output of dozens of skilled workers, significantly reducing labor costs. From precise coating, to film lamination and pressing, to precise cutting and automatic stacking and counting of the film paper, the entire process does not require manual intervention. Moreover, all parameters of the equipment can be adjusted, allowing for adjustments in product thickness and diameter, and being able to precisely match regional taste preferences, enabling traditional delicacies to regain new vitality in modern production.

Why choose Chenpin?

"Helping customers generate profits" is the business philosophy that Chenpin has always adhered to.

"Embracing innovation and change in research and development" is the core strategy it adopts to cope with the market.

In Chenpin, there are no "standard answers", only tailor-made solutions.

Chenpin Machinery integrates the "customization" concept into every aspect of equipment research and development. Whether it's adjusting power specifications, changing product sizes, or meeting special process requirements, the Chenpin engineering team can provide professional solutions. Chenpin Machinery redefines the efficiency of food production with innovative technologies and the concept of customization, bringing new opportunities for food enterprises.

Post time: Jun-16-2025

Phone: +86 21 57674551

Phone: +86 21 57674551 E-mail: sales@chenpinsh.com

E-mail: sales@chenpinsh.com![Y5[98K8IZ$]AE`8_~L02Q{5](https://www.chenpinmachine.com/uploads/Y598K8IZAE8_L02Q5.png)